Description

DT-6B table top vacuum seal machine (tray sealer) is a special type tray of modified atmosphere packaging machines.

It is a tray sealer with vacuum and gas flushing for multiple shop, super market and small scale food manufacturer. The collections, operation, drive form and security aspects are according with these shops and manufacturer requirement and characters.

Application of Tray Sealer

DT-6B table top vacuum seal machine can be used for fresh-keeping packing of different types of fresh and cooked food. The type and mixing proportion of fresh keeping gas are different for different types according to the food’s characteristics.

DT-6B modified atmosphere packaging machines is applicable to controlled atmosphere fresh-keeping packing of cool fresh meat, cooked meat products, fast food, pastry, rice noodle, cheese, soy products, aquatic products, poultry and other foods.

Technical Characters of Tray Sealer

1. Control System: OMRON PLC programmable control system.

The data setting and motion control are more accurate and the performance is more reliable, so the operation is easier.

2. Table top vacuum seal machine could be running after pushing the mould into machine.

3. Vacuum System

Germany BUSCH vacuum pump (high oxygen vacuum pump) is equipped with high vacuum degree and long service life to assure reliable quality.

4. Structure Material: The main structure material adopts 304 Stainless Steel. It is safe and easy to clean.

5. Work status indication: the vacuum seal machine has an operating program status and failure real-time display function to monitor the equipment and ensure the normal operation.

Technology Specification

|

Model

|

DT-6B Table Top Vacuum Seal Machine

|

|

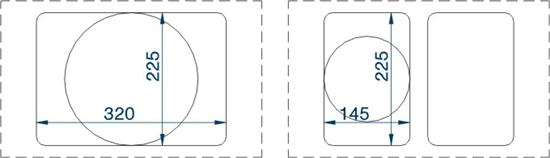

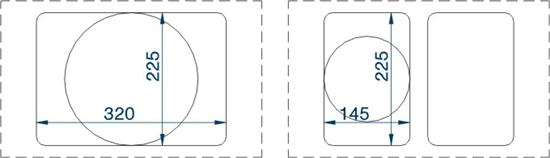

Max Tray Dimensions(mm)

|

320 × 225 × 60

|

|

Max Width of Film(mm)

|

410

|

|

Max Diameter of Film(mm)

|

260

|

|

Packaging Speed(times/min)

|

2 to 5

|

|

Electrical Requirement

|

1P/220V/50HZ

|

|

Consume Power(kW)

|

2.8

|

|

Vacuum Pump(m³/h)

|

20

|

|

Air Exchanging Rate (%)

|

99

|

|

Air Filling Concise (%)

|

≤2

|

|

Main Machine Dimensions(mm)

|

800 × 640 × 810

|

|

Main Machine Weight(kg)

|

197

|

|

Gas Mixer System Dimensions(mm)

|

650 × 650 × 470

|

|

Gas Mixer System Weight (kg)

|

90

|

Die Plates Available Format