Description

DT-6A map tray sealer (vacuum seal machine) adopts Germany BUSCH vacuum pump (high oxygen vacuum pump). When the oxygen ratio is up to 21%, it needs to be equipped with Germany high oxygen vacuum pump. Furthermore, because of the ratio of oxygen is too high, the machine could avoid the accident of deflagration.

Application of Vacuum Seal Machine

DT-6A map tray sealer is widely applicable to fresh meat, cooked meat, fish, poultry, shellfish, fruit, coffee, tea, vegetables, bread, and supermarket-distribution foods.

Technical Characters of Vacuum Seal Machine

1. Electric System

France Schneider Electric Elements features long service life and high applicability to assure reliable quality.

2. The Germany WITT gas mixer

It adopts real-time gas mixing, which accuracy is higher than ± 1%. The quality of food packing of each box is guaranteed to be always consistent. The preservation period of the packed food are controlled effectively.

3. High vacuum degree and long service life assures reliable quality of map tray sealer

4. Gas displacement system

The totally enclosed vacuum chamber gas replacement technology is used to guarantee the high replacement rate (replacement rate ≥ 99%).

5. Gas displacement system can minimize the residual oxygen content within the packing pallet and effectively guarantee the mixing precision of the mixed gas within the food packing pallet.

6. User can effectively control the storage, logistics and sales time of the fresh food, and prolong the shelf life accordingly.

7. Easily replaceable of sealing mould: Different size of the trays is available according to different requirements.

8. Removable modified atmosphere box: Removable vacuum and gas mixing system is convenience for machine installation.

Technology Specification

|

Model

|

DT-6A Map Tray Sealer

|

|

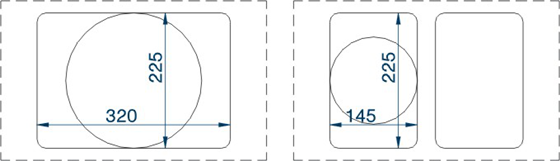

Max Tray Dimensions(mm)

|

320 × 225 × 60

|

|

Max Width of Film(mm)

|

410

|

|

Max Diameter Of Film(mm)

|

300

|

|

Packaging Speed(times/min)

|

3 to 4

|

|

Electrical Requirement

|

1P/220V/50HZ

|

|

Consume Power(kW)

|

2.5

|

|

Vacuum Pump(m³/h)

|

20

|

|

Air Exchanging Rate (%)

|

99

|

|

Air Filling Concise (%)

|

≤1

|

|

Main Machine Dimensions(mm)

|

800 × 640 × 810

|

|

Main Machine Weight(kg)

|

162

|

|

Gas Mixer System Dimensions(mm)

|

655 × 600 × 550

|

|

Gas Mixer System Weight(kg)

|

90

|

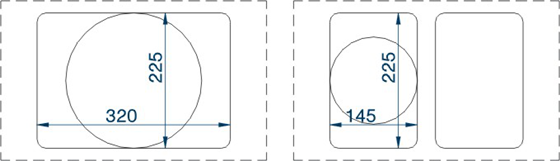

Die Plates Available Format